A Chinese

Forging Company

Backed by over three

decades of industry experience, Longchao delivers dependable, custom forging solutions tailored to your needs.

We have a large team of experienced forging engineers and skilled technicians.

Equipped with a wide range of forging machines, we can mass-produce die-forged parts from 0.1kg to 2T.

Our industrial design department can develop new products or optimize existing ones based on customer requirements to achieve optimal performance.

Your Trusted Forging Partner

Longchao is a professional forging company based in Zhangqiu District, Jinan, Shandong Province, with over 30 years of experience. We specialize in custom-forged components ranging from 0.1kg to 2T, serving various industries worldwide.

multiple production lines, 100 skilled employees, and complete in-house facilities—including tooling, CNC machining, heat treatment, and testing—we ensure consistent quality and on-time delivery.

Our forged products are trusted by top OEMs and exported to the USA, Europe, Japan, and other global markets. Longchao is your reliable partner for high-quality, cost-effective forging solutions.

Recent Forged Parts

Let Longchao help you reduce costs and improve performance with our custom forging solutions.

We offer a variety of solutions

From automotive and aerospace to agriculture, valves, and industrial tools—Longchao provides tailored forging solutions to meet the specific needs of different industries.

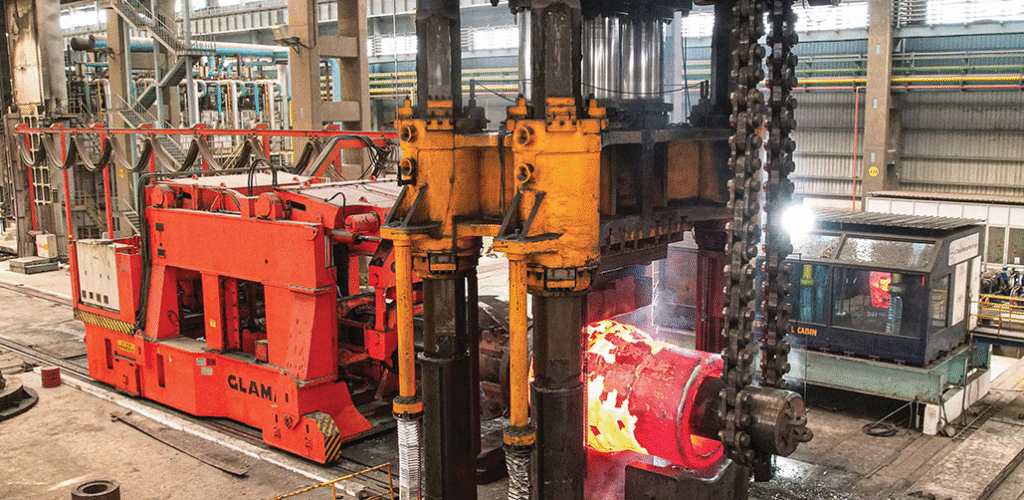

Forged components play a key role in industrial machinery, where high strength and durability are critical under heavy loads and repetitive motion. Forgings are widely used in construction equipment, mining machinery, presses, and material handling systems.

Common forged parts include drive shafts, gears, spindles, rollers, couplings, and bearing housings. These components are typically made of alloy steel and heat-treated to meet specific performance requirements such as wear resistance, fatigue strength, and impact toughness.

In automotive applications, forged components are widely used in areas subject to high impact and stress. A typical vehicle can contain over 250 forged parts, most of which are made from carbon or alloy steel.

These parts are essential in engine and drivetrain assemblies, including connecting rods, crankshafts, transmission shafts and gears, differential gears, drive shafts, clutch components, universal joints, and cross shafts.

Additional forgings such as camshafts, pinions, gears, and rocker arms are often selectively hardened to enhance performance and durability.

The oil and energy sector demands forged components that can perform reliably under extreme pressure, temperature, and corrosive environments. Forgings are used in drilling equipment, valve bodies, flanges, pump parts, and pipeline components.

Due to the harsh operating conditions, components are often made from high-strength alloy steels or stainless steel, with precision machining and rigorous testing to meet international standards such as API, ASME, and NACE. Forged parts enhance safety, reduce failure rates, and extend equipment life in oilfields and power plants.

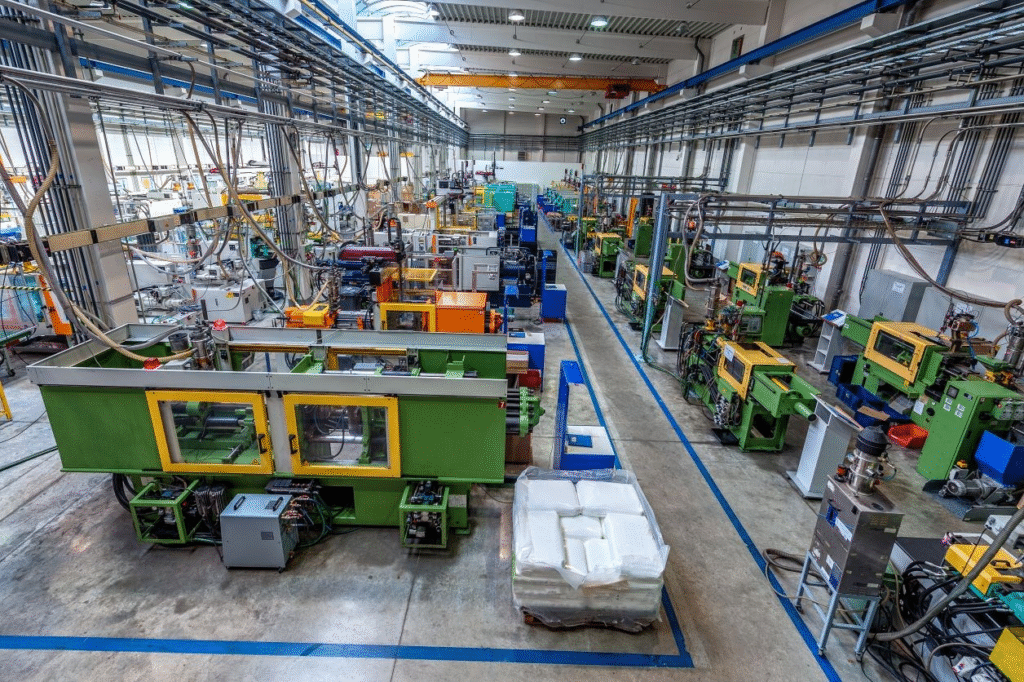

Forgings are essential in a wide range of general-purpose industrial equipment, including pumps, compressors, gearboxes, and lifting systems. These applications require parts that combine strength, precision, and cost-efficiency.

Typical forged components include shafts, gear blanks, flanges, yokes, and brackets. With flexible production capabilities, Longchao can meet both low- and high-volume demands while maintaining consistent quality for various equipment manufacturers.

Submit a Quick Quote

Why Longchao is Trusted by 1000+ Clients

Our forging solutions deliver a wide range of benefits across multiple industries and applications. Here’s why clients around the world rely on Longchao for high-quality forged components.

We produce custom-forged parts for aerospace, automotive, energy, and industrial equipment. With in-house tooling and machining, we ensure fast turnaround, precise tolerances, and consistent quality.

Our forging process enhances the mechanical properties of metal—resulting in components with excellent strength-to-weight ratios, impact resistance, and long service life, even in demanding environments.

From carbon steel to titanium alloys, we support a broad range of materials and forged shapes. Our expertise in hot forging, CNC machining, and surface treatments ensures every part meets your exact specifications.

Our Blog

Insights, updates, and practical tips from the world of metal forging. Stay informed about our latest projects, industry trends, and custom manufacturing solutions.

The Future of Flanges: Innovation and Industry Trends

Flanges are critical

Testimonials

“I was looking for a reliable forging partner for a critical project, and Longchao exceeded expectations. The lead time was fast, the parts met all our specs, and the communication was excellent throughout.”

from Germany

“We’ve sourced forged parts from several suppliers, but Longchao stands out for their quality and flexibility. They helped us optimize our design and reduced overall costs without compromising strength.”

from USA

“Longchao delivered precisely machined forged components right on time. The surface finish and dimensional accuracy were exactly what we needed. Great supplier to work with.”

Japan

Frequently Asked Questions

Q1: What types of forged products can you provide?

We specialize in custom-forged components ranging from 0.1kg to 2T, including shafts, flanges, yokes, gears, couplings, and more for various industries.

Q2: What materials do you offer for forging?

We work with carbon steel, alloy steel, stainless steel, aluminum alloy, copper alloy, titanium alloy, and other non-ferrous metals based on your specifications.

Q3: Can you assist with design or provide technical support?

Yes. Our in-house engineering team can assist with drawings, DFM (design for manufacturability), material selection, and process optimization to meet your performance and cost requirements.

Q4: What is your typical lead time?

For standard orders, lead time is usually 25–35 days. Urgent or trial production can be expedited depending on your needs and project complexity.

Q5: Do you provide machining and surface treatment?

Absolutely. We offer CNC machining, heat treatment, polishing, painting, powder coating, and plating—all performed in-house for quality control and efficiency.

Q6: What are your quality control standards?

We conduct incoming material analysis, in-process checks, dimensional inspections, hardness testing, and final packaging inspection. Certifications like ISO 9001 and IATF16949 support our quality system.